Job

Company

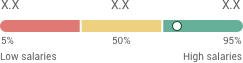

Salary

Applicant Insights

Job Description

The main responsibilities are:

- Define and maintain the optimum process parameters to ensure the maximum efficiency of equipment and production by the quality standards set by the company and the technical conditions.

- After defining all needed parameters, the process engineer will build the operating procedures and organize the workplaces to make sure that the production team can meet the expected performance maintaining the expected quality standard.

- Introduce proposals for the introduction of advanced technological processes, types of equipment and technological equipment, automation equipment, and optimal production modes for products.

- Participate in developing process sheets and changeover matrixes.

- Make proposals on the organization of workplaces to reduce labor costs and improve sanitation and hygiene.

- Propose production technology improvement.

- Participate in conducting trial and industrial tests of new types of packaging materials, raw materials, and finished products.

- Participate in/lead improvement projects, study WCM tools, and apply them in practice in improvement projects.

- Participate in the HACCP program, develop measures to reduce risks, and guarantee consumer safety in the unit.

- Monitor the standards of the state of production and auxiliary equipment.

- Identify the causes of equipment malfunctions or defects.

- Participate in the training of production operators. Participate in the annual certification of production operators.

- Develop and maintain a reporting system and working documentation regarding the production process functionality.

- Develop and support the production team to create and update WCM activity boards.

- Advise and support, in cooperation with the WCM coordinator, and production staff on the application of WCM techniques.

- Participate in conducting internal meetings aimed at developing measures to prevent and eliminate non-conformities and reduce losses.

- Analyze the causes of process failure, loss of packaging materials, raw materials, and finished products as well as poor quality products or incidents in quality. Takes part in the development of measures to prevent and eliminate them in the production process, as well as in consideration of incoming complaints for products with the department of quality assurance.

- After identifying the causes of equipment malfunctions or defects, if necessary, take part in the repair, installation, dismantling, testing, and adjustment of particularly complex units of equipment (units and machines) in cooperation with maintenance.

- Immediately inform the immediate supervisor of any detected deviations from the normal operation of the equipment and malfunctions.

- Participate in projects to upgrade existing equipment, as well as purchase new ones.

- Check and assess the needs of the production line in connection with the optimization of the line.

- Constant communication with the enzyme coordinator and reporting to her.\

- Check for any line changes and compare with normal enzymatic conditions.

- Check the dedusting system for continuous optimization.

- Confirm risk assessment of changes.

- Responsible and authorized for process safety as a PC process engineer.

Requirements

- Bachelor's or Master's degree in Mechanical and Electrical Engineering.

Preferred:

- Experience in statistics and process control tools.

- Experience in AM, PM, Quality, and FI tools and processes

Professional Skills:

- Ability to analyze and optimize supply chain performance to create value.

- Ability to optimize performance and networks through virtual sites.

- Ability to deliver and implement factory change including innovation.

- Ability to manage and benchmark production performance to defined standards.

- Ability to optimize and manage site-specific manufacturing processes.

- Ability to manage regulatory compliance.

- Ability to improve WCM principles objectives and target setting.

- Ability to implement and integrate WCM Pillars.

- Ability to use WCM cost deployment/linking WCM loss and cost concepts to benefits.

- Ability to apply WCM principles to the extended supply chain and Innovation.

- Ability to manage process safety hazards and risks in manufacturing.

- Knowledge of system design and modeling.

Employment Type

- Full Time

Job Category

Seniority

Details

Employment type

- Full Time

Job Category

Seniority

To see more jobs that fit your career

To see more jobs that fit your career

Candidate

Irantalent Products

Employer

© 2025 IranTalent.com All rights reserved. Terms and Conditions Head Hunting Terms & Conditions Privacy policy